METALLIC GASKET

Metallic gaskets cannot be punched out of sheets but are still cheap to produce. These gaskets generally have a much higher level of quality control than sheet gaskets and generally can withstand much higher temperatures and pressures. Metal must be greatly compressed in order to become flush with the flange head and prevent leakage. The material choice is more difficult; because metals are primarily used, process contamination and oxidation are risks. Metallic gasket used must be softer than the flang in order to ensure that the flange does not warp and thereby prevent sealing with future gaskets.

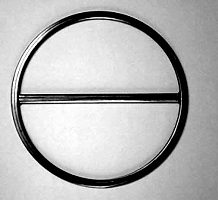

R type

R type ring Joint gaskets comprises of two types such as Oval cross section and an Octagonal cross section. These types of gaskets are used in pressures up to 10,000 PSI. The dimensions are standardized and require specially grooved flanges. Sealing occurred in Octagonal cross section with the wedge contact, Oval cross section with single line contact. The flat bottom groove design will accept both the Octagonal and Oval cross section. The sealing surfaces on the Ring Joint Gasket and Grooves must be smoothly finished to 63 micro inches and to be free of objectionable ridges, tool or chatter marks.

Bx type

The BX Ring Gasket differs from the standard RX, Oval or Octagonal shape since it is square in cross section and tapers in each corner. BX is used at pressures up to 20,000 PSI. The BX Gaskets will have pressure relief hole at mid portion of C. The sealing surfaces on the Ring Joint Gasket and Flange Grooves must be smoothly finished to 32 micro inches and to be free of objectionable ridges, tool or chatter marks.

Rx type

RX ring gaskets are similar in shape to the standard octagonal ring joint gasket but their cross section is designed to take advantage of the contained fluid pressure in effecting a seal. They are both made to API 6A and interchangeable with standard Octagonal and Oval rings for oil field drilling and production applications in API 6B flanges. RX is used at pressures up to 5,000 PSI. The sealing surfaces on the Ring Joint Gasket and Grooves must be smoothly finished to 63 micro inches and to be free of objectionable ridges, tool or chatter marks. The hardness of the Ring Gaskets should always be less than the hardness of the flanges to prevent flange deformation. Dimensions Ring Joint Gaskets are covered in ASME B16.20 and API 6A standard. These Gaskets are used in ASME B16.5 flanges, API 6B flanges and API 6BX flanges.

Rubber Coated type

Rubber coated Ring Gasket (usually steel) used in pressure testing to minimize damage to flanges. The rubber contact points provide additional seals while protecting the flange surfaces.

Grooved Metal Gasket

Concentric 'V' Grooves on the flat metal. Pitch of the Groove normally 1 to 1.5mm, groove depth will be 0.4 to 0.7mm. These gasket required Top of the 'V' Groove 0.1 to 0.2mm flat will give required to seal. Grooved metal Gaskets are sealing occurred by metal to metal contact. These Gaskets are normally much softer than flange material. The surface finish of the flange material are lesser than 63 micro inches. These Gaskets required high seating stress. These Gaskets required more bolt load than any other Gaskets. Every Groove will acts as separate seal.

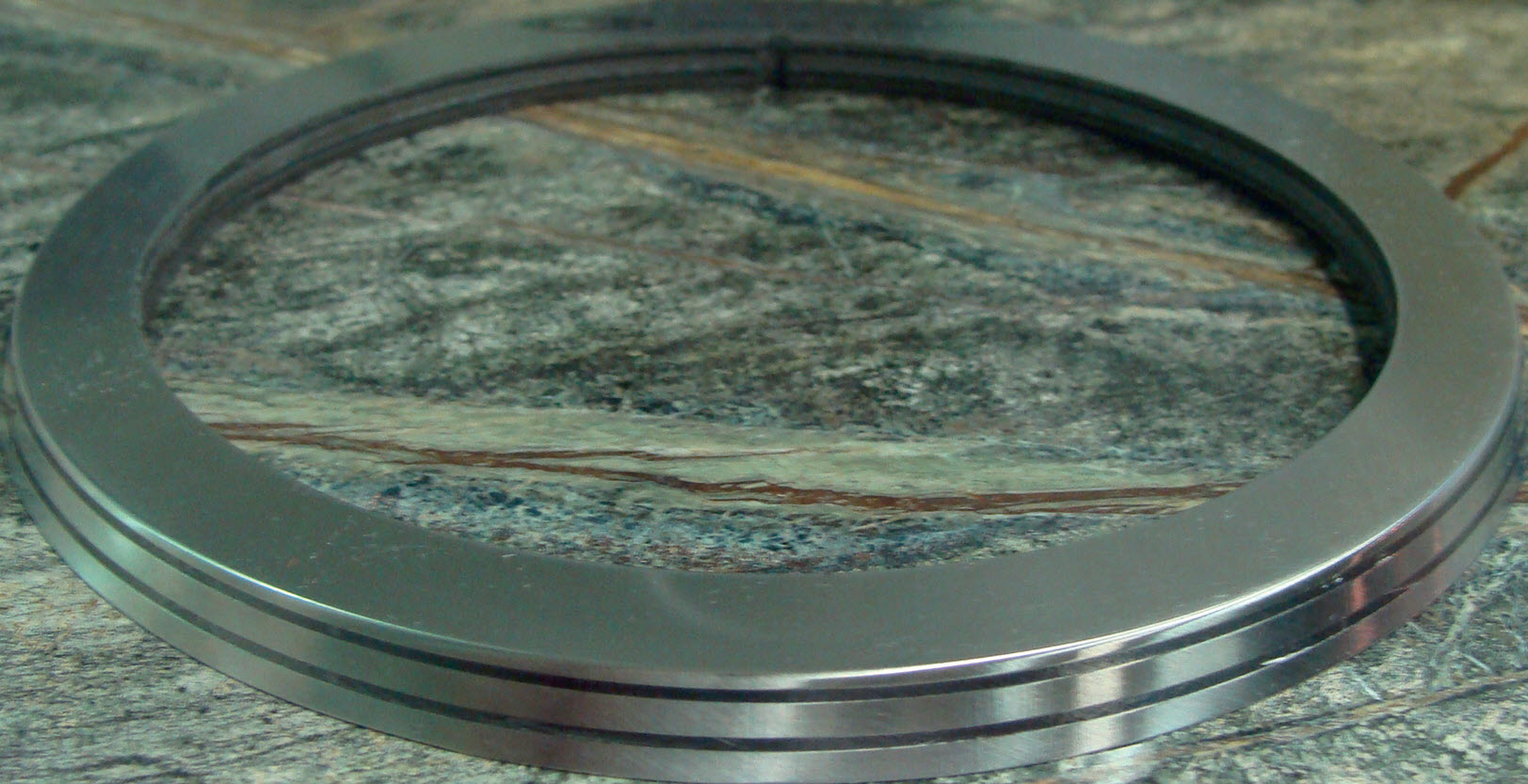

Lens Gasket

A lens type gasket is a line contact seal for use in high pressure piping systems and in pressure vessel heads. The lens cross section is a spherical gasket surface and requires special machining on the flanges. These gaskets will seat with a small bolt load since the contact area is very small and gasket seating pressures are very high. Normally the gasket materials should be softer than the flange. In ordering lens gaskets, complete drawings and material specifications must be supplied.

DELTA GASKET

A delta gasket is a pressure actuated gasket used primarily on pressure vessels and valve bonnets at very high pressures in excess of 5000 PSI. As with the lens gasket, complete drawings and material specifications must be supplied. Internal pressure forces the gasket material to expand when the pressure forces tend to separate the flanges. Extremely smooth surface finishes of 63 micro inches or smoother are required when using this type of gasket.

SEMI METALLLIC GASKET

Semi Metallic Gaskets are designed to feature soft ,elastic sealing materials which enhance the tightness of assembly with lower load requirements when compared to metallic gaskets. This type of gasket has unique specialty because of its wide range of size and types. They can be fabricated of any metal. Semi Metallic gaskets can generally be used in various pressure class flange ratings according to ASMEb16.5 standards. They rebounds readily from any deformation that happens due to temperature gradients, variations of pressure and vibration.

Ex-R type (Only Gasket)

Excellent Gasket provides this type as only the Gasket. A winding with an alternate combination of a STEEL strips and a soft non-metallic FILLER. The metal strip in the gasket is performs superior resiliency and self-adjustment when compared to conventional gaskets. This type is just a sealing component (winding with filler) only, which is normally used on tongue and groove joints, male and female facings and groove to flat flange facings.

Ex-CG type (Gasket with Outer Ring)

Excellent Gasket provides this type Gaskets, consist of a Gasket (Winding + Filler) with a solid metal OUTER guide ring. A winding with an alternate combination of a STEEL strips and soft non-metallic FILLER with Solid Outer Guide Ring. These gaskets can be used on plain flat face flanges and on raised face flanges. The outer guide ring serves to center the gasket properly in the flange joint, acts as an anti-blowout device and compression gauge to prevent Spiral wound gasket to prevent the Spiral Wound component from being crushed. Normally the outer guide rings are furnished in mild steel (Carbon Steel), but can be supplied in other metal when required by operating conditions.

Ex-GI type (Gasket with Inner Ring)

Excellent Gasket provides this type Gaskets, consist of a Gasket (Winding + Filler) with a solid metal Inner Ring. A winding with an alternate combination of a STEEL strips and soft non-metallic FILLER with Solid Inner Ring. The inner ring also serves several functions. Primarily, it provides radial support for the gasket on the Inner diameter to help prevent the occurrences of inside buckling, collapsing and imploding. Its Inner diameter is normally sized slightly larger than the Inner diameter of the flange bore, minimizing turbulence avoiding uneven flow. The inner rings are normally supplied in the same material as the winding strips in spiral wound component. This Gasket mostly used in tongue and Groove flanges,Valves and pumps.

Ex-CGI type (Gasket with Inner and Outer Ring)

Excellent Gasket provides this type Gaskets, consist of a Gasket (Winding + Filler) with a solid metal Inner and OUTER guide ring. A winding with an alternate combination of a STEEL strips and soft non-metallic FILLER with Solid Inner and Outer Guide Ring. This type CGI is identical to style CG, with the addition of an INNER ring. The inner ring also serves several functions. Primarily, it provides radial support for the gasket on the Inner diameter to help prevent the occurrences of inside buckling, collapsing and imploding. Its Inner diameter is normally sized slightly larger than the Inner diameter of the flange bore, minimizing turbulence avoiding uneven flow. The inner rings are normally supplied in the same material as the winding strips in spiral wound component.

Ex-ONGI (Gasket with Inner Ring & Outer Nose)

Excellent Gasket provides this type Gaskets, consist of a Gasket (Winding + Filler) with Nose (Bare) Outer winding a solid metal Inner Ring and OUTER bare (Nose) winding. A winding with an alternate combination of a STEEL strips and soft non-metallic FILLER with Solid Inner Ring and Outer Nose (Bare) winding. This type Gaskets are mostly used in Heat exchangers where the minimum space available. Primarily, it provides radial support for the gasket on the Inner diameter to help prevent the occurrences of inside buckling, collapsing and imploding. Its Inner diameter is normally sized slightly larger than the Inner diameter of the flange bore, minimizing turbulence avoiding uneven flow. The inner rings are normally supplied in the same material as the winding strips in spiral wound component. Outer Nose Winding is used material same as of winding metal.

Ex-ONG (Gasket with Outer Nose)

Excellent Gasket provides this type Gaskets, consist of a Gasket (Winding + Filler) with Nose (Bare) Outer winding a solid metal winding as OUTER bare (Nose) winding. A winding with an alternate combination of a STEEL strips and soft non-metallic FILLER with solid Outer Nose (Bare) winding. This type Gaskets are mostly used in Heat exchangers where the minimum space available. The Inner diameter of Gasket larger than the flange bore; Outer Nose Winding is used as same material of winding metal. In some type where partition plates are available, the gasket shall have partition ribs made out of double jacketed or solid metal. For these drawing or details must be given by Customer.

Type WGR

Kammprofile gasket of this type is manufactured without a guide ring it is comprised of a core metal of any specification as required with concentric grooves on both sides that covered with Graphite or Expanded PTFE. It is typically used in heat exchanger applications and applied as an upgrade to double jacketed gaskets or Exchanger spiral wound gaskets especially when lower load is needed. When partition required same shall be attached with inner diameter of grooved ring.

Type IGR

Kammprofile gasket of this type is fabricate with an integral guide ring for aligning purposes. It is suggested to be used in raised face flanges. The Gasket comprised of a core metal of any specification as required with concentric grooves on both sides that covered with Graphite or Expanded PTFE. The sealing core is designed and sized per ASME B16.20, EN-12560-6 spec and depending on the flange specification the guide ring is sized to fit properly.

TYPE LGR

Kammprofile gasket of this type is processed along with a loose fitting guide ring. This popular design is preferred to be used for nominal pipe size and pressure class raised face flanges and is used in equipment with excessive radial shear characteristics, thermal cycling, and expansions. . The Gasket comprised of a core metal of any specification as required with concentric grooves on both sides that covered with Graphite or Expanded PTFE. The sealing core is designed and sized per ASME B16.20, EN-12560-6 spec and depending on the flange specification the loose fit guide ring is sized to fit properly. Also Kammprofile gaskets can be applied to high pressure up to very high temperature applications which is rated to 1500ºF.

DOUBLE JACKETED GASKET

Excellent Double Jacketed gaskets used for heat exchangers and large vessels. The Double Jacketed Gaskets consists of jacketed metal encapsulate with soft filler. The Double jacketed Gaskets are designed as per ASME B16.20. Double Jacketed gaskets to ASME B16.20, designed to suit ASME B16.5 and ASME B16.47 flanges. Mostly used on Equipments, boiler and heat exchangers. Other non-standard Gaskets are manufactured as per customer specific requirements. Excellent Gasket manufactures all shapes with different partition as per customer requirements.

NON METALLIC GASKET

Non Metallic Gasket generally termed as SOFTCUT GASKETS whose material is easily compressed under a low bolt load. This term has been used to distinguish the difference from a metallic gasket. A soft gasket material can be selected from a large variety of elastomers, compressed non-asbestos, PTFE, flexible graphite and high temperature sheet products.Soft cut gaskets are used in a wide range of applications such as for pipe flanges, heat exchangers, compressors and bonnet valves.This kind of gasket can be available in a variety of cut shapes or be provided in sheet or rolls.

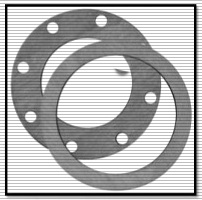

COMPRESSED NON-ASBESTOS (CNAF) GASKET

Excellent Gasket provides Asbestos free (CNAF) cut Gaskets for serrated finish flanges for all pressure rating. Excellent Gasket normally manufactures Ring Type (Inside Bolt Circle), Full Face (Entire Face of Flange with bolt holes) and Tailor made (As per Drawing). These gaskets manufactured to ASME B16.21, designed to suit ASME B16.5 and ASME B16.47 flanges. DIN 1514-1 and EN 12560-1 and BS flanges. Other non-standard Gaskets are manufactured as per customer specific requirements. Excellent Gasket has better team to design and manufacture as per customer requirements. These Gaskets are available for all the Services.

RUBBER GASKET

Excellent Gasket manufactures Rubber cut Gaskets, Ring Type (Inside Bolt Circle), Full Face (Entire Face of Flange with bolt holes) and Tailor made (As per Drawing). These gaskets manufactured to ASME B16.21, designed to suit ASME B16.5 and ASME B16.47 flanges. DIN 1514-1 and EN 12560-1 and BS flanges. Other non-standard Gaskets are manufactured as per customer specific requirements. Excellent Gasket has better team to design and manufacture as per customer requirements. These Gaskets are available for all the Services. Rubber Gaskets available in all the Grade of rubber ie. Natural, Chloroprene (Neoprene), Nitrile (NBR), SBR, EPDM, Silicon, Viton, Butyl, Buna-N etc.

PTFE GASKET

Excellent Gasket manufactures PTFE, Ring Type (Inside Bolt Circle), Full Face (Entire Face of Flange with bolt holes) and Tailor made (As per Drawing). These gaskets manufactured to ASME B16.21, designed to suit ASME B16.5 and ASME B16.47 flanges. DIN 1514-1 and EN 12560-1 and BS flanges. Other non-standard Gaskets are manufactured as per customer specific requirements. Excellent Gasket has better team to design and manufacture as per customer requirements. These Gaskets are available for all the Services. This Gasket are suitable for fluids PH 0-14. PTFE have with filler like carbon, silica, barium as special application. PTFE envelop Gasket can be provided with suitable insert.

EXPANDED PTFE GASKET

Excellent Gasket manufactures Expanded PTFE, Ring Type (Inside Bolt Circle),Full Face(Entire Face of Flange with bolt holes) and Tailor made (As per Drawing). These gaskets manufactured to ASME B16.21, designed to suit ASME B16.5 and ASME B16.47 flanges. DIN 1514-1 and EN 12560-1 and BS flanges. Other non-standard Gaskets are manufactured as per customer specific requirements. Excellent Gasket has better team to design and manufacture as per customer requirements. These Gaskets are available for all the Services. This Gasket are suitable for fluids PH 0-14

GRAPHITE GASKET

Excellent Gasket manufactures Graphite, Ring Type (Inside Bolt Circle), Full Face (Entire Face of Flange with bolt holes) and Tailor made (As per Drawing). These gaskets manufactured to ASME B16.21, designed to suit ASME B16.5 and ASME B16.47 flanges. DIN 1514-1 and EN 12560-1 for BS flanges. Other non-standard Gaskets are manufactured as per customer specific requirements. Excellent Gasket has better team to design and manufacture as per customer requirements. These Gaskets are available for all the Services. This Gasket is suitable for high temperatures.

INSULATION GASKET AND KITS

Excellent Gasket manufactures insulation Gaskets and it is full kit for entire flange. Full gasket kit set consists of One insulating gasket, One full length sleeve per bolt, Two insulation washer per bolt, Two steel washer per bolt. This Gasket manufactured Ring Type (Inside Bolt Circle), Full Face (Entire Face of Flange with bolt holes) and RTJ for RTJ flanges. These Gaskets are used for preventing conduction (Physical, Electrical and Thermal) between flanges even through bolts.

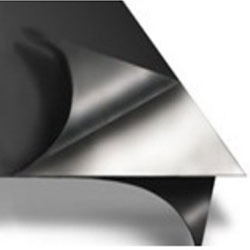

STEEL INSERT SOFT LAYER COVERED GASKET

Excellent Gasket manufactures this type Gaskets; consist of steel with soft layer laminated on top and bottom face of gasket faces. Steel provide sufficient strength and soft layer provides sufficient seal between flanges. These gaskets are manufactured Ring Type (Inside Bolt Circle), Full Face (Entire Face of Flange with bolt holes) and Tailor made (As per Drawing). These gaskets manufactured to ASME B16.21, designed to suit ASME B16.5 and ASME B16.47 flanges. DIN 1514-1 and EN 12560-1 for DIN and BS flanges. Other non- standard Gaskets are manufactured as per customer specific requirements. Some of different shape also available likes Oval, Elliptical and Rectangular for Valve bonnet & manholes.

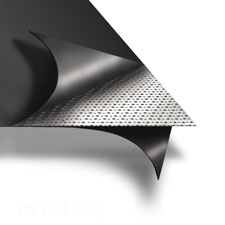

SOFT LAYER WITH TANGED INSERT GASKET

Excellent Gasket manufactures Ring Type (Inside Bolt Circle), Full Face (Entire Face of Flange with bolt holes) and Tailor made (As per Drawing). These gaskets manufactured to ASME B16.21, designed to suit ASME B16.5 and ASME B16.47 flanges. DIN 1514-1 and EN 12560-1 for DIN and BS flanges. Other non- standard Gaskets are manufactured as per customer specific requirements. Excellent Gasket has better team to design and manufacture as per customer requirements. These Gaskets are available for all the Services. This Gasket are best with good strength (metal inside) with proper sealing (soft Layer).

CORRUGATED WITH SOFT LAYER SHEATHED GASKET

Excellent Gasket manufactures this type Gaskets; consist of corrugated steel with soft layer laminated on top and bottom face of corrugation faces. Steel provide sufficient strength and soft layer provides sufficient seal between flanges. These gaskets are manufactured Ring Type (Inside Bolt Circle) and Tailor made (As per Drawing). These gaskets manufactured to ASME B16.21, designed to suit ASME B16.5 and ASME B16.47 flanges. DIN 1514-4 and EN 12560-4 for DIN and BS flanges. Other non-standard Gaskets are manufactured as per customer specific requirements. Some of different shape also available likes Oval, Elliptical and Rectangular for Valve bonnet.

SANDWICH GASKET

Excellent Gasket manufactures this type Gaskets; consist of two are multiple layers are sandwiched as per customer requirements. The sandwich may be solid metal with soft material or solid metal thin sheets are also used. This type Gaskets are mostly used in Heat exchangers where the minimum space available. The Inner diameter of Gasket larger than the flange bore.